polySML: structure & machine learning for polymer materials

This suite of standalone software is to predict mechanical, thermal, conductivity, filtration and separational etc. properties for variant polymer materials.

Requirements

Win7/vista/win8/win10 64-bit operating system, 105M RAM, 400M storage

Download Url: https://github.com/polySML/polySML/releases/download/v0.0.1/PolySML.zip

It takes time to load, please be patient.

Usage

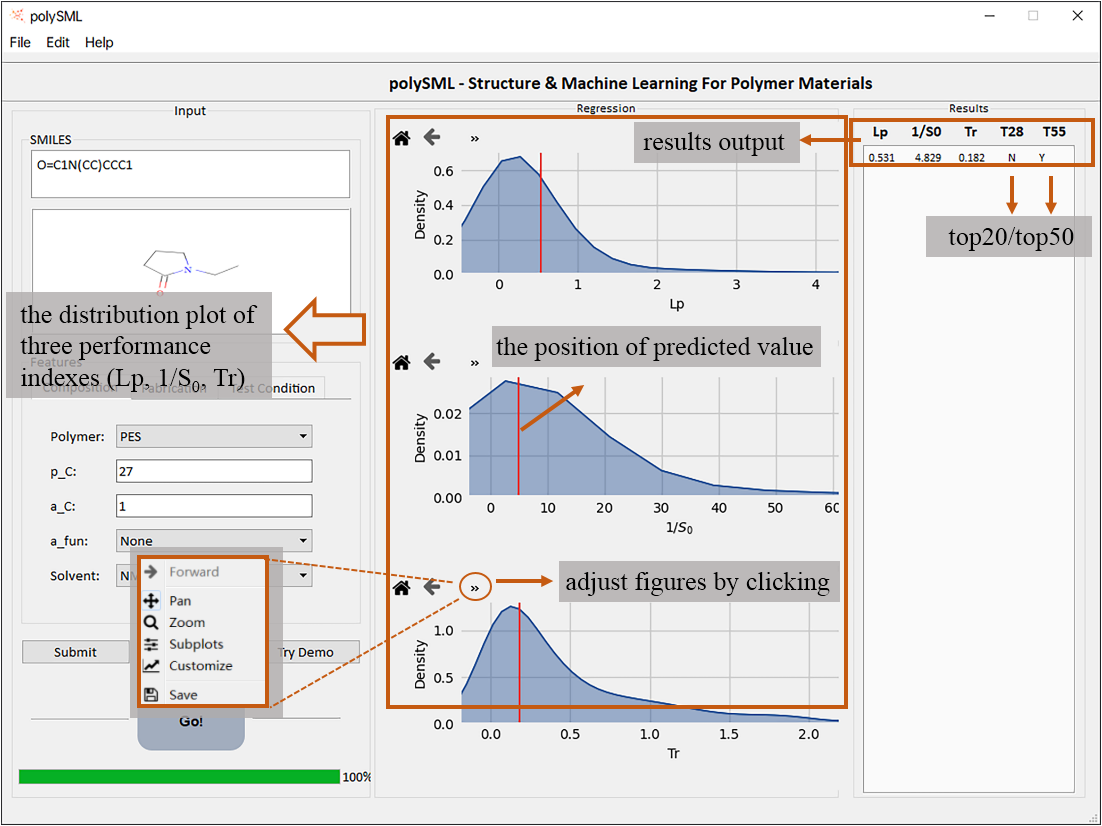

This model provides the prediction for three critical performance indexes accounting micro-/ultra-/nano-filtration membranes and the evaluation of the overall membrane performance grade.

-

Input correct SMILES for addictive in polymer solution (SMILES can be queried from Pubchem https://pubchem.ncbi.nlm.nih.gov/ ).

-

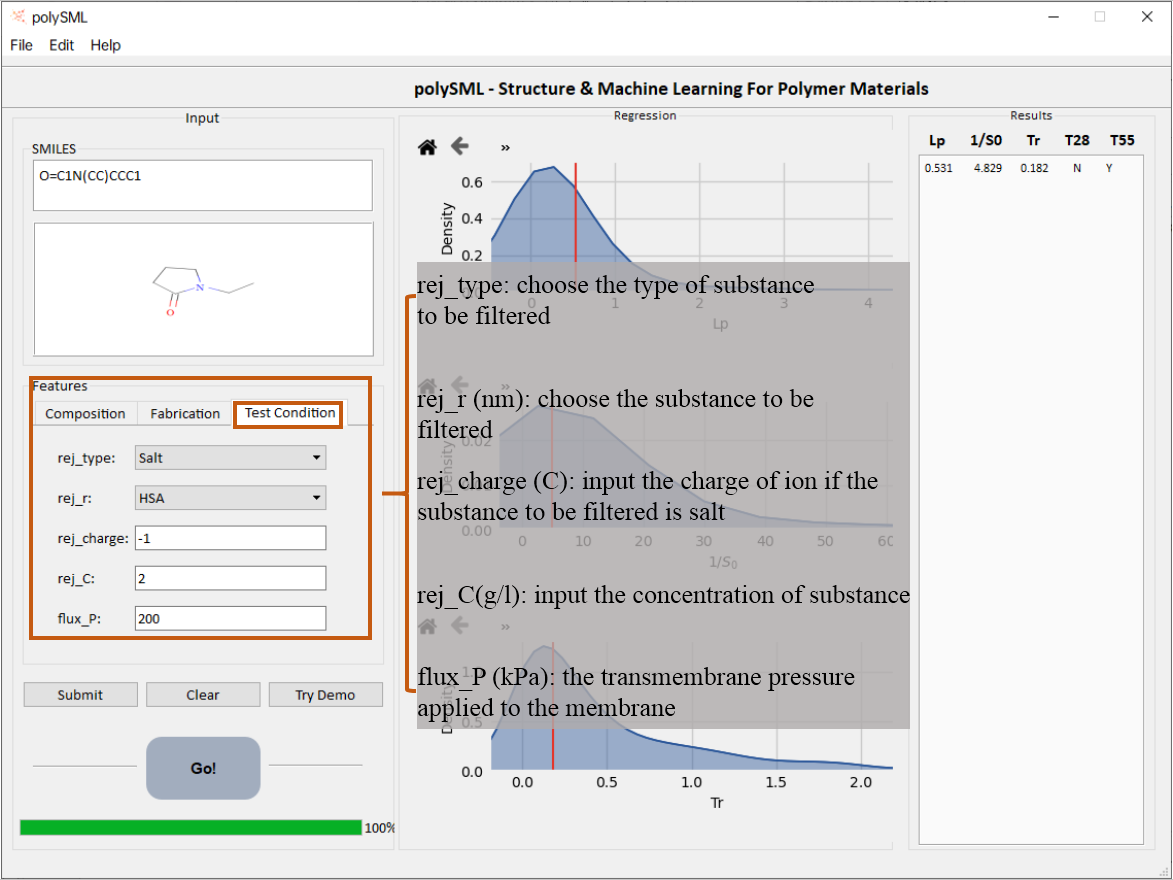

Parameters for composition, fabrication and test condition.

-

Click Submit and check all the inputs correct.

-

Click GO for predictions.

-

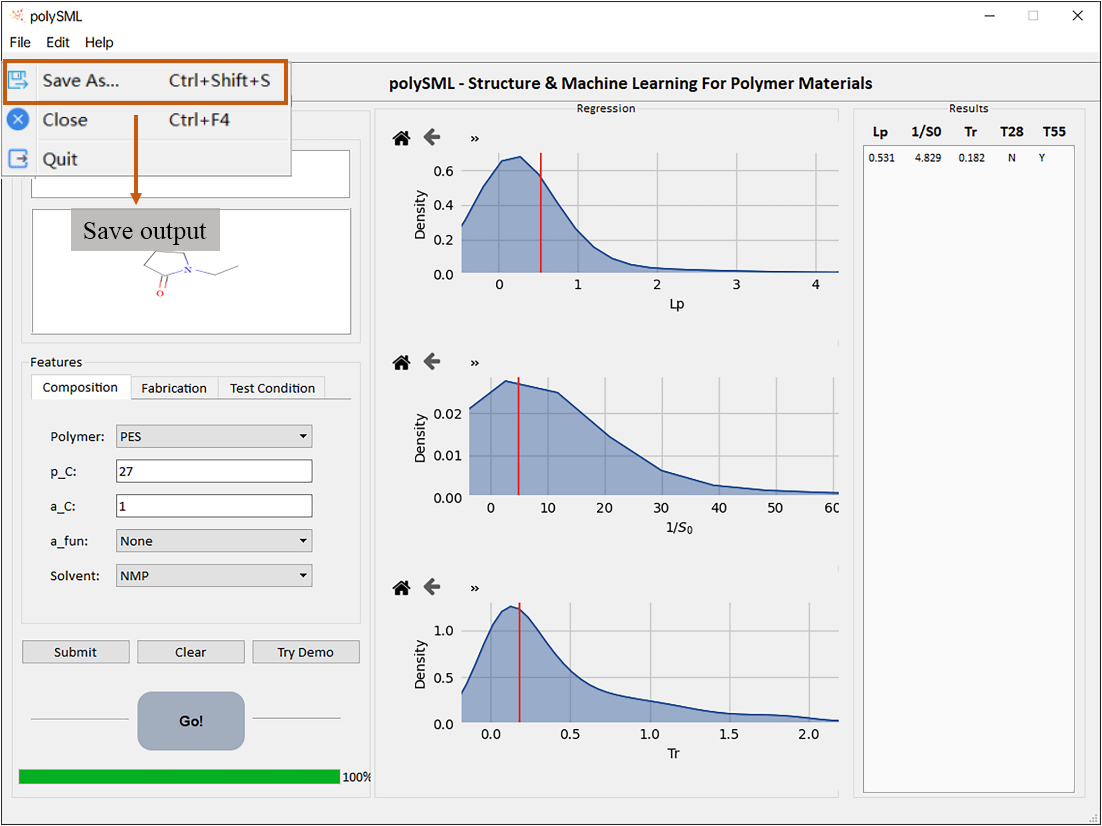

Click Save As to save outputs.

Predictor: WFM_poly

This model provides the prediction for three critical performance indexes accounting micro-/ultra-/nano-filtration membranes and the evaluation of the overall membrane performance grade.

Regression models

Permeability(Lp)

The permeability of membrane is defined as: $$ Lp=Jv/(ΔP×p_0)Lp=Jv/(ΔP×p_0) $$

Where $Jv$ is the volumetric filtrate flux $(m/s)$, $ΔP$ is the transmembrane pressure (Pa), $p0$ is the unit permeability coefficient ($1ms^{−1}Pa^{−1}$)

Selectivity(1/S01/S0)

The selectivity of membrane is defined as: $$ 1/S_0=1/(1−R)=C_f/C_{p1}/S_0=1/(1−R)=C_f/C_p $$

Where R is the rejection ratio (%), $Cp$ and $Cf$ are the concentrations of substances in the permeation and feed flux (wt%).

Trade-off coefficient(Tr)

The trade-off coefficient of membrane is defined as: $$ Tr=(2×Lp×1/S_0)/(Lp+1/S_0)Tr=(2×Lp×1/S_0)/(Lp+1/S_0) $$

Classification models

According to the “trade-off curve”, we got four curves which can divide the macromolecules and salts data points into 50:50 and 20:80. The output result is “Y” means that the performance of the membrane is above the trade-off curve, on the contrary, the result is “N”.

Features

Features used for prediction models are listed below:

| ID | Feature | Unit | Description |

|---|---|---|---|

| 1 | p_C | wt% | The weight fraction of base polymer in casting solution |

| 2 | a_C | wt% | The weight fraction of the addictive in casting solution |

| 3 | s_C | wt% | The weight fraction of the solvent in casting solution |

| 4 | s_Disp | - | Hansen solubility parameter (Dispersion force for solvent) |

| 5 | p_Disp | Hansen solubility parameter (Dispersion force for monomer in polymer) | |

| 6 | RED_S | The relative energy difference between base polymer and solvent | |

| 7 | RED_NS | The relative energy difference between base polymer and non-solvent | |

| 8 | Bp | $^oC$ | Boiling point for solvent and non-solvent |

| 9 | Vp | mmHg | The saturated vapor pressure at 25$^oC$ for solvent and non-solvent |

| 10 | HDT | $^oC$ | Heat Deflection Temperature with loading of 1.8MPa |

| 11 | coag_T | $^oC$ | The temperature of coagulation bath |

| 12 | pre_T | $^oC$ | The temperature during membrane formation |

| 13 | exposed.time | s | The exposed time before immersing the casting solution into the non-solvent |

| 14 | wet_mem_thick | μm | The thickness of solution on the substrate controlled by the scraper |

| 15 | flux_P | kPa | Transmembrane pressure in performance measurement |

| 16 | rej_C | wt% | The concentration of substance (protein, salt etc,) in feeding flux |

| 17 | rej_type | The type of separation substance | |

| 18 | rej_charge | C | The charge of separation substance |

| 19 | rej_r | nm | The radius of rejection substance |

| 20 | porosity | % | Volume fraction of water accessible voids in membrane |

| 21 | CA | o | Water static contact angle on membrane surface |

License

The copyright for this software suite is owe to the authors, academic free for current version and commercial usages please contact the corresponding author yunqi@ciac.ac.cn.

References

User are encouraged to cite the following references for special predictors.

-

Liu L, Liu T, Ding F, Zhang H, Zheng J & Li Y Exploration of the polarization curve for proton-exchange membrane fuel cells, ACS Appl. Mater. Interfaces, 2021, 13(49) 58838–58847

-

Liu T, Liu L, Cui F, Ding F, & Li Y Predict the performance of polyvinylidene fluoride, polyethersulfone and polysulfone filtration membranes using machine learning, J. Mater. Chem. A, 2020,8, 21862-21871

-

Liu L, Chen W, Liu T, Kong X, Zheng J, & Li Y Rational design of hydrocarbon-based sulfonated copolymers for proton exchange membranes J. Mater. Chem. A, 2019 7:11847-11857.

-

Liu L, Chen W, & Li Y A Statistical Study of Proton Conduction in Nafion?-based Composite Membranes: Prediction, Filler Selection and Fabrication Methods J. Membr. Sci., 2018 549:393-402.

-

Liu L, Chen W, & Li Y An overview of the proton conductivity of nafion membranes through a statistical analysis J. Membr. Sci., 2016 504:1-9.

Release log: 201912 version v0, construct the UI and common block. WFM_poly model was integrated. 202003 version v1.0.0 predictor about polymer materials for water filtration membranes(WFM_poly) was integrated.

Limitation

Current models mainly focus on the types of polymers, additions, solvents reported. For novel compounds, chemical structures, predictions are made based on knowledge, confidence needs validation in blind-test. We are not guarantee the prediction is fully accurate but guidelines are possible.

Bug report and suggestions

Please contact either lyliu@ciac.ac.cn or yunqi@ciac.ac.cn for bugs or suggestions.

About us

We are a research group didicate in structure and machine learning study on polymer materials. We are welcoming suggestions and collaborations. Contact Prof. Yunqi Li for further information.