PolySML: structure & machine learning for polymer materials

This suite of standalone software is to predict mechanical, thermal, conductivity, filtration and separational etc. properties for variant polymer materials.

1 Requirements

Windows operation systems, including Win7/vista/win8/win10 64Bit, at least 800M RAM and 1G free disk space needed.

2 Usage

2.1 Main interface

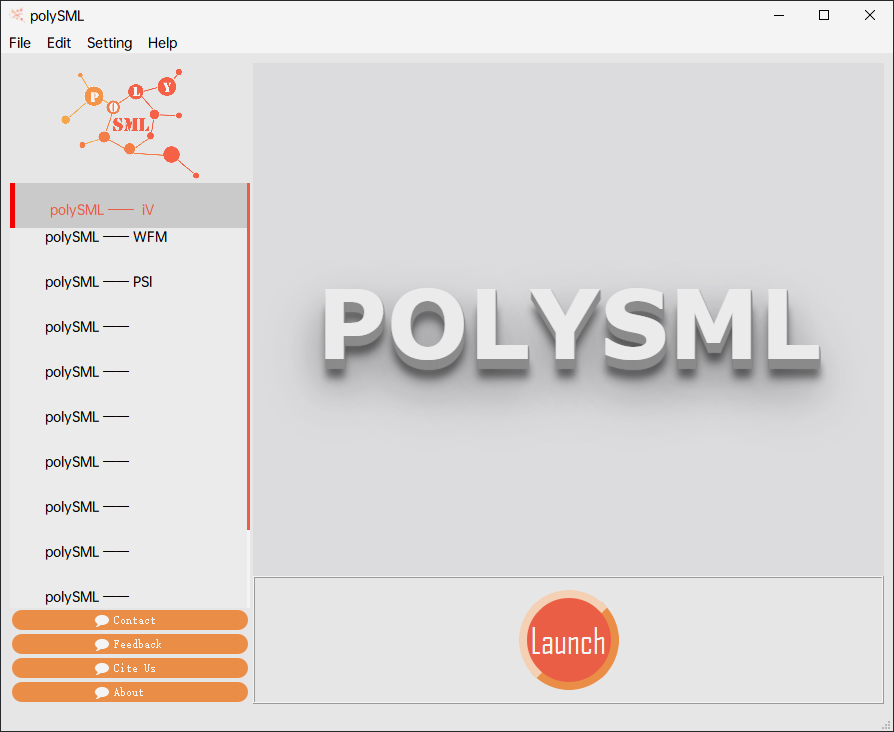

After starting polySML and closing the Splash Screen your polySML window should look something similar to the image below.

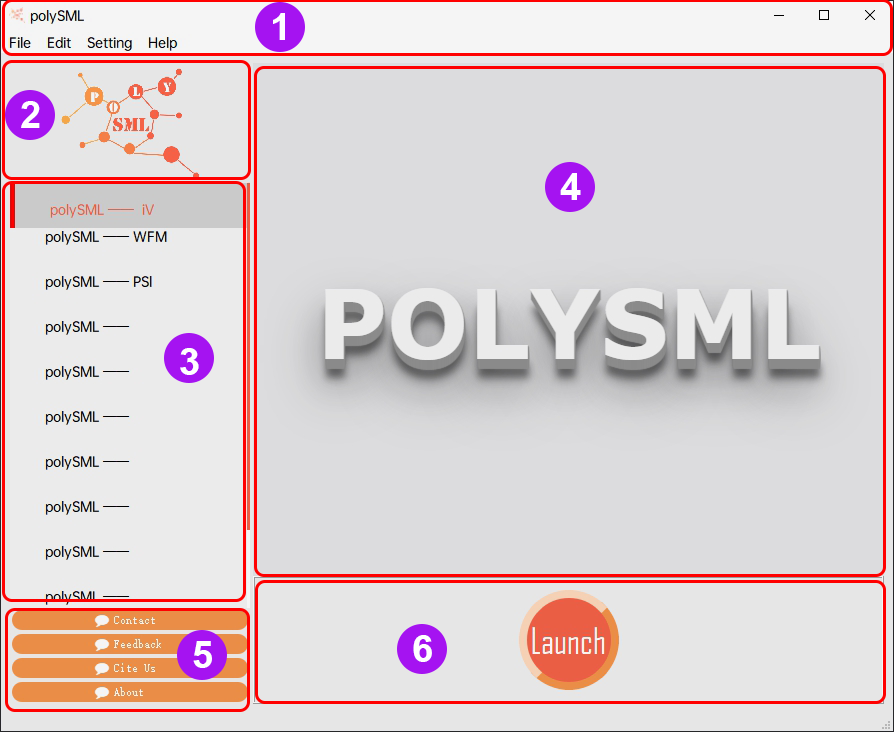

By default polySML starts up showing the default screen, which is separated into six areas:

-

The menu bar at the top.

-

A large Logo.

-

Model list at the left.

-

Model information at the middle.

-

Contact, feedback, cite us and about buttons at the bottom left.

-

A big button to launch the selected model.

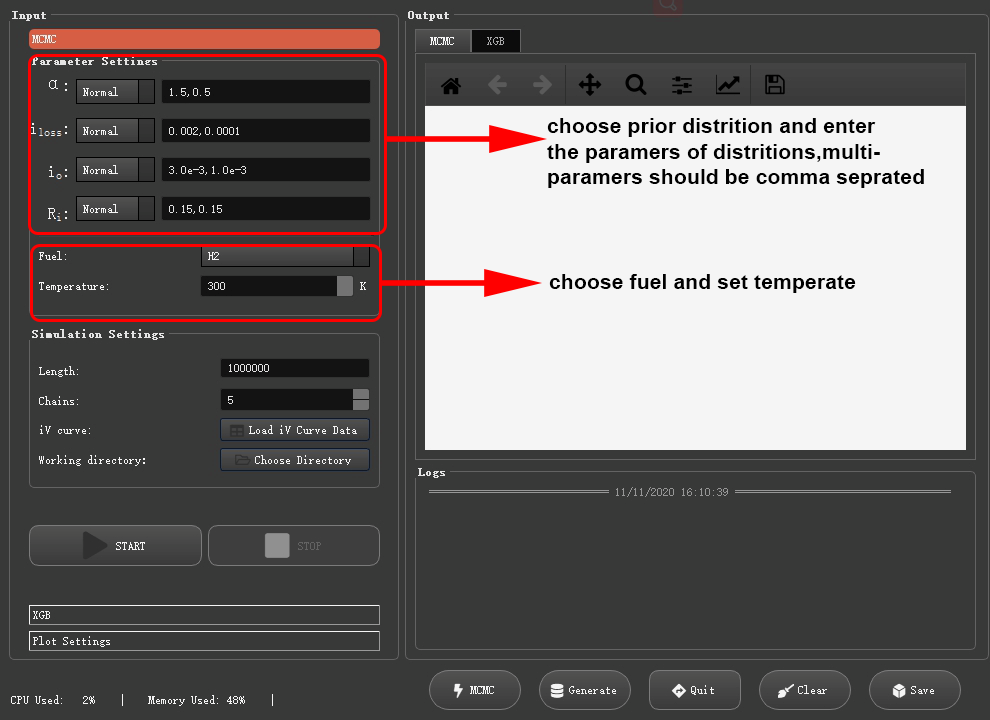

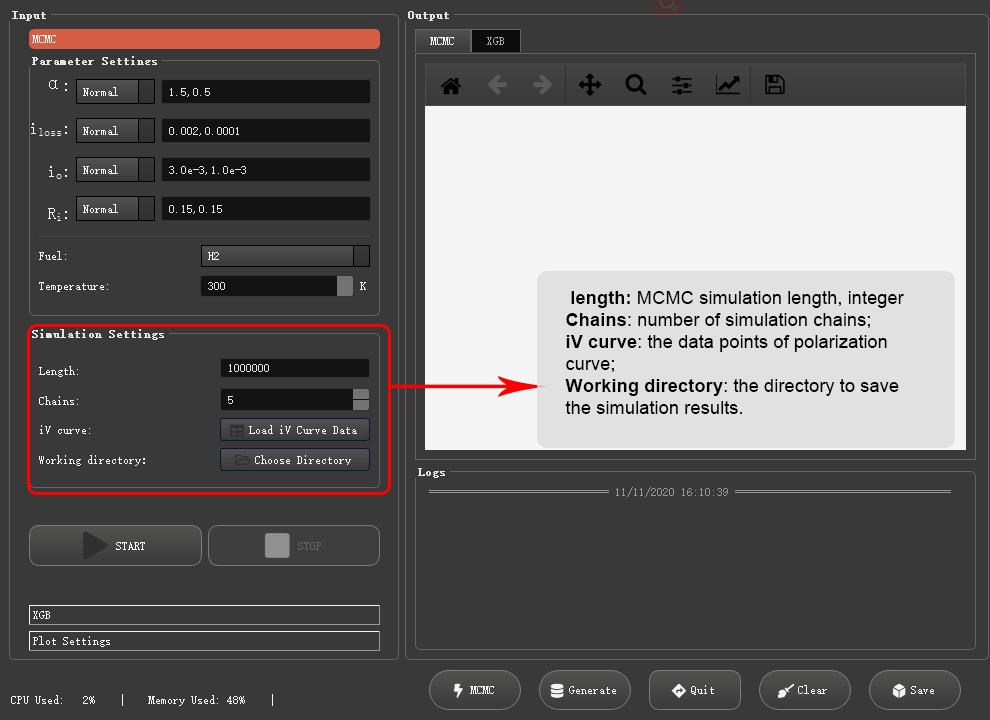

2.2 MCMC simulation interface

- Set the mcmc simulation parameters:

- MCMC simulation work settings:

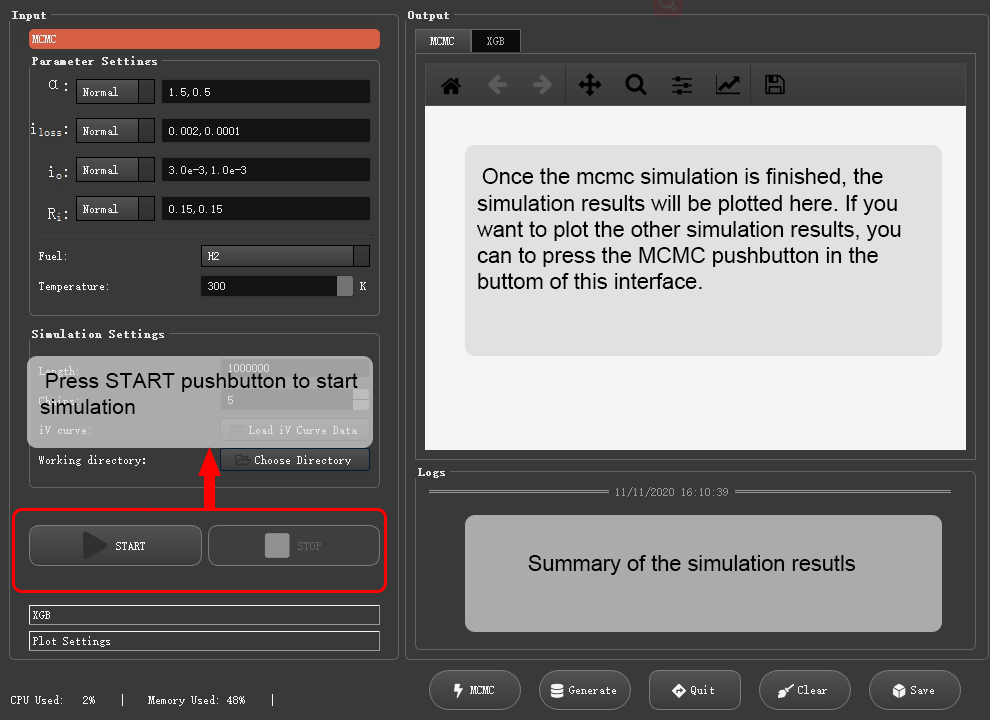

- start simulation by pressing the START pushbutton. After the simulation is running, the STOP pushbutton is activated, you can terminate simulation at any time.

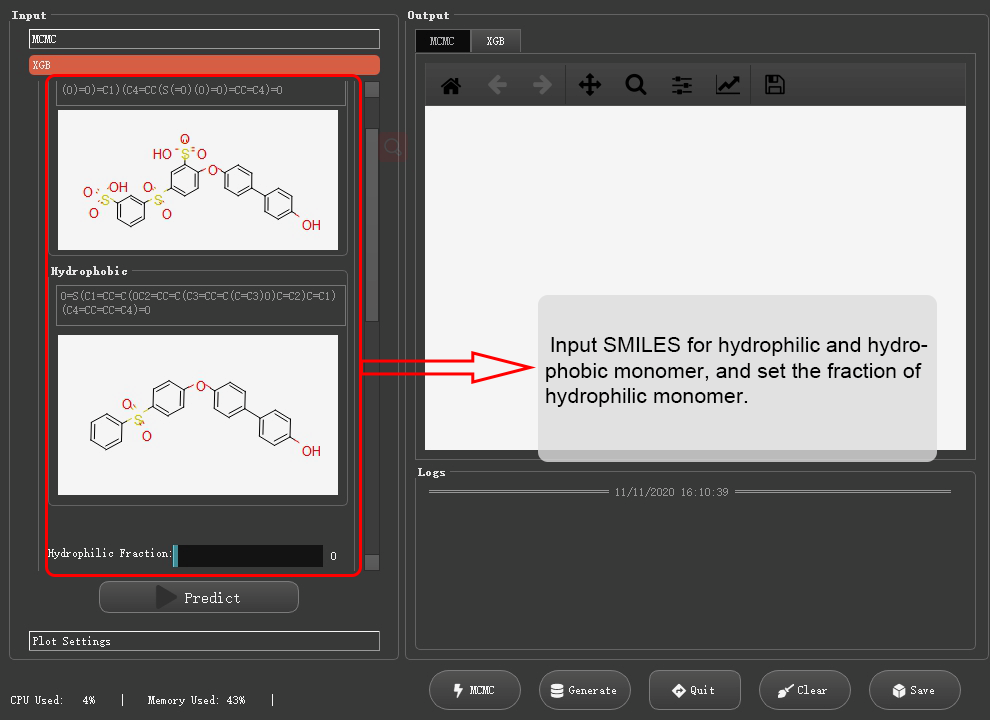

2.3 XGB prediction interface

- Input correct SMILES for hydrophilic and hydrophobic monomer

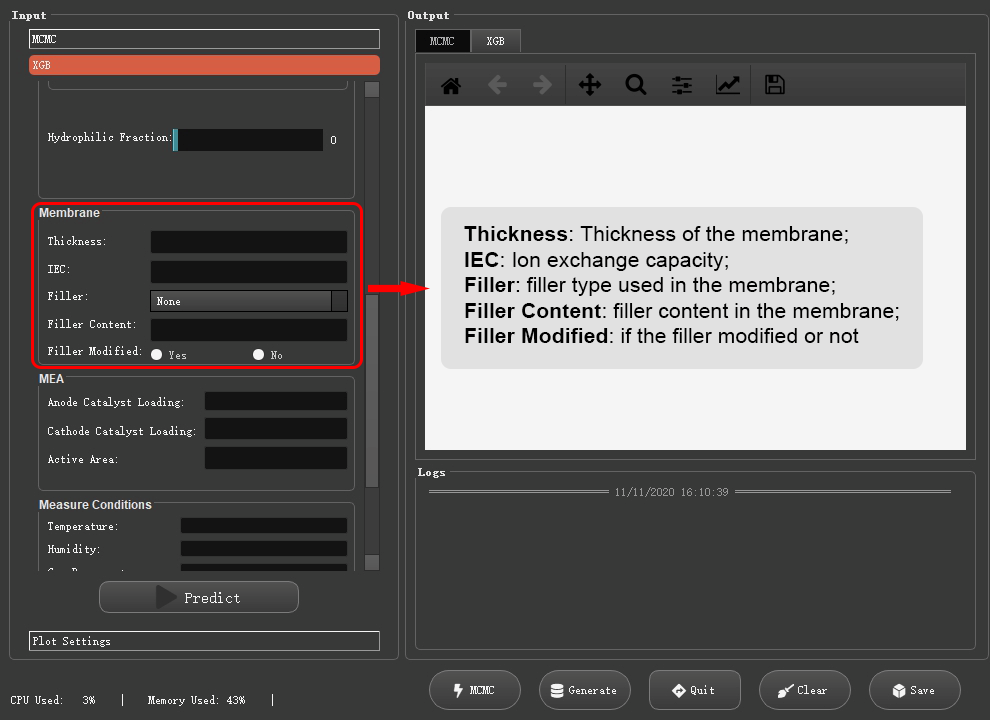

- Input membrane properties

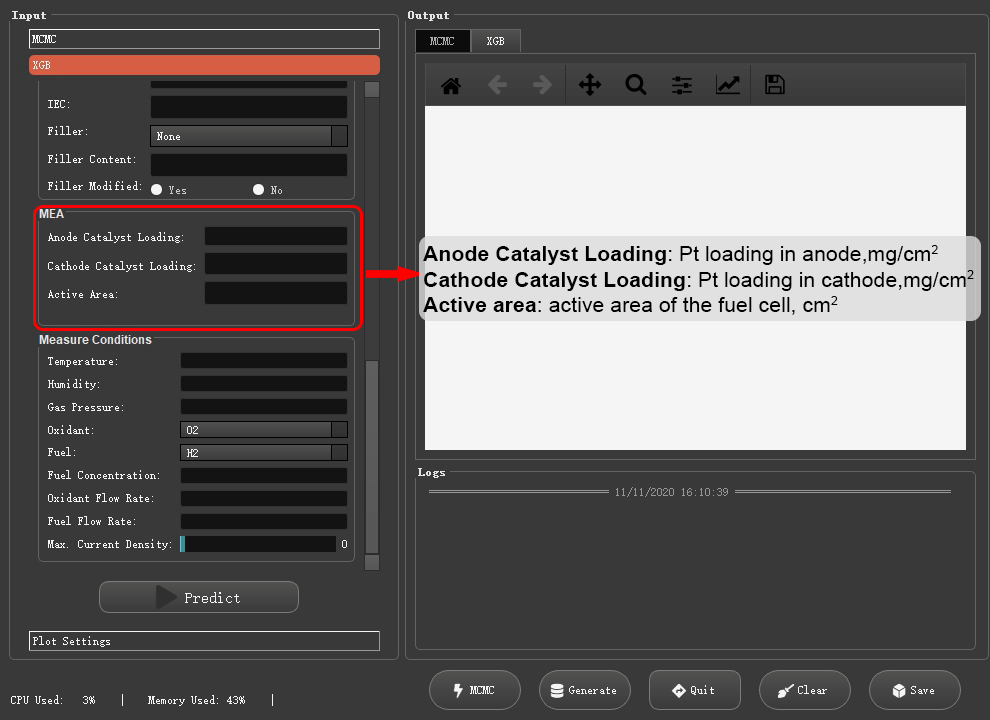

- Input MEA information:

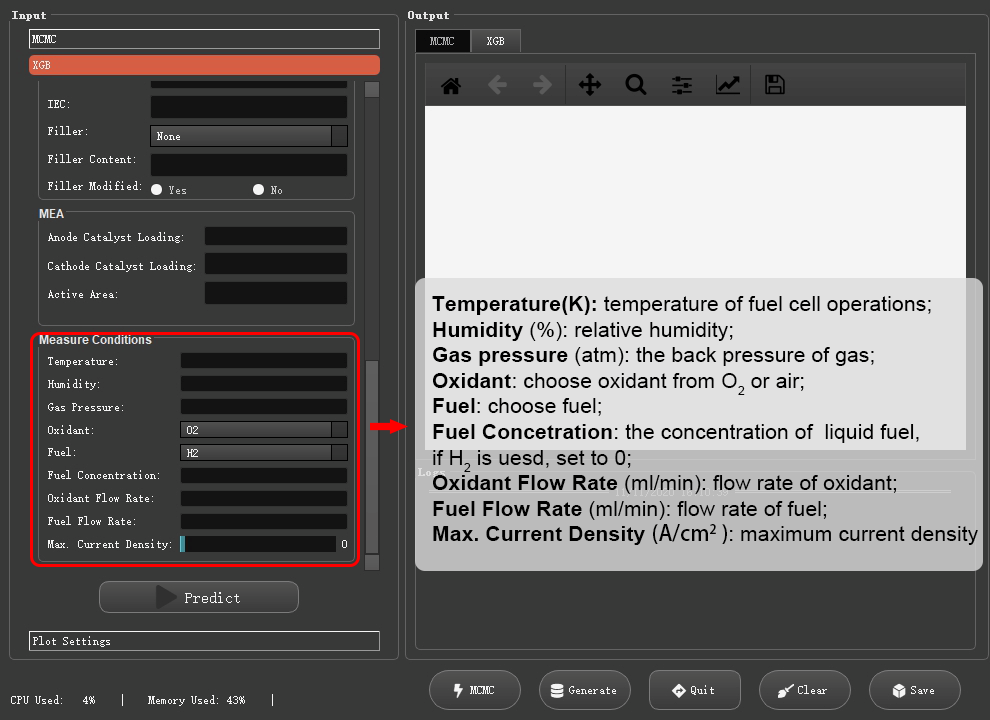

- Input the measure conditions of fuel cell:

- Prediction and generate membrane sample data.

When all the inputs are set completely and correctly, then press the Predict pushbutton to submit the prediction task. You can also generate the demo samples by pressing the Generate button.

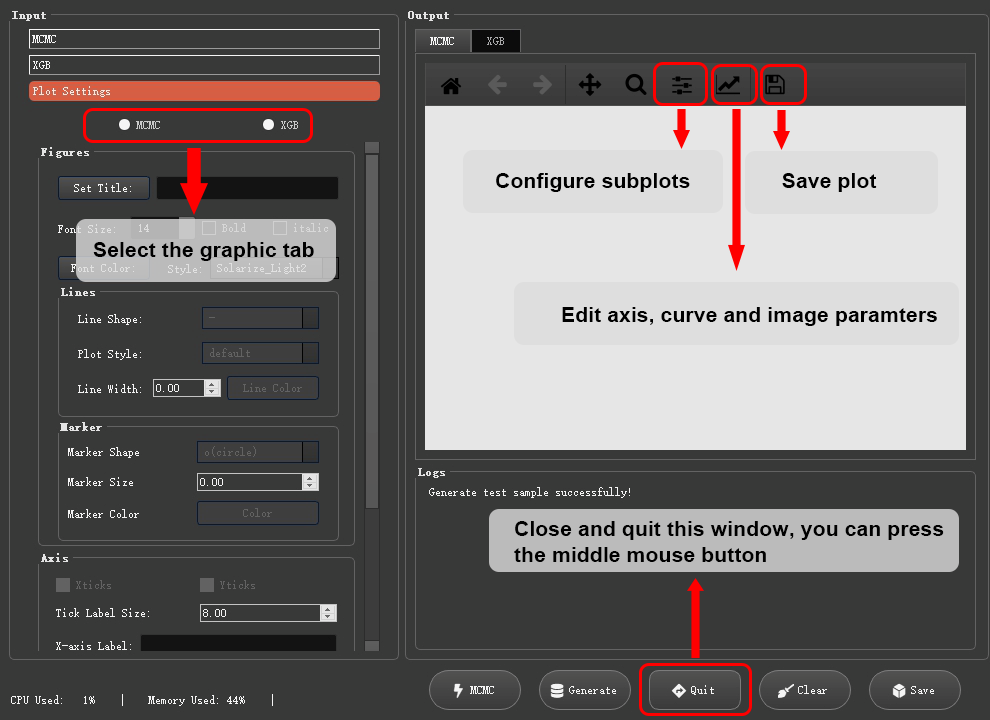

2.4 Graphic setting interface

Setting plot parameters and exporting the graphs.

3 Predictor: polySML-iV

This model provides the description of polarization curve with Markov chain Monte Carlo simulation method and the prediction of polarization curve for proton exchange membranes with the state-of-art machine learning algorithm.

3.1 Description of polarization curve

The fuel cell voltage output can be described by the Butler-Volmer (BV) equation: $$ V_{cell} = E_r - \frac{RT}{\alpha F}ln(\frac{i+i_{losss}}{i_o})-iR_i-\frac{RT}{nF}ln(\frac{i_L}{i_L-i}) $$ where $V_{cell}$ is the real output voltage($V$) at the current density of $i$($A/cm^2$), $E_r$ is the reversible open-circuit potential ($V$), $α$ is the transfer coefficient to describe the ratio of forward to reverse reaction influenced by potential difference, $i_{loss}$ is current loss, $i_o$ is reference exchange current density, $R_i$ is the internal resistance, $i_L$ is limiting current density. $R$ is gas constant (8.314 $J mol^{-1} K^{-1}$), $T$ is temperature($K$), $F$ is Faraday’s constant (96, 485 $C/mol$), $n$ is number of electrons involved, equals 2 for fuels of $H_2$ and formic acid, 6 for methanol and 12 for ethanol.

3.2 Prediction of the polarization curve

Features:

| Features for PEM | |

|---|---|

| MaxEStateIndex | Maximum EState indices for the molecule, encode electronic and topological information |

| MinEStateIndex | Minimum EState indices for the molecule, encode electronic and topological information |

| MinAbsEStateIndex | Minimum absolute EState indices for the molecule |

| qed | quantitative estimate of drug-likeness |

| MolWt | The molecule’s molecular weight. |

| BertzCT | A topological index meant to quantify “complexity” of molecules |

| philicFra | Ratio of hydrophilic monomers in copolymer |

| FiMolecularWeight | Molecular weight of filler |

| FiHBAC | Hydrogen bond acceptor count of filler |

| fillerModi | If filler was modified |

| fillerCont | Content of filler |

| memThick | Membrane thickness |

| memIEC | Ion exchange capacity of copolymer |

| Features for MEA | |

| actArea | Active area of membrane electrode assembly (cm2) |

| anCataLoad | Catalyst loading in anode (mg/cm2) |

| caCataLoad | Catalyst loading in cathode (mg/cm2) |

| Features for Operation | |

| AnRate | Flow rate of fuel (ml/min) |

| CaRate | Flow rate at oxidant (ml/min) |

| humidity | Relative humidity (%) |

| Pressure | Back pressure (MPa) |

| FuelConc | Concentration of fuel (M) |

| temperature | Temperature for measurements (K) |

| O2Air | Oxidant, oxygen or air |

4 License

The copyright for this software suite is owe to the authors, academic free for current version and commercial usages please contact the corresponding author yunqi@ciac.ac.cn.

5 References

Users are encouraged to cite the following references for special predictors.

- Liu L, Liu T, Ding F, Zhang H, Zheng J & Li Y Exploration of the polarization curve for proton-exchange membrane fuel cells, ACS Appl. Mater. Interfaces, 2021, 13(49) 58838–58847

- Liu T, Liu L, Cui F, Ding F, & Li Y Predict the performance of Polyvinylidene fluoride, ployethersulfone and polysulfone micro/ultra/nano-filtration membranes, 2020, J. Mater. Chem. A, 2020, 8,21862–21871.

- Liu L, Chen W, Liu T, Kong X, Zheng J, & Li Y Rational design of hydrocarbon-based sulfonated copolymers for proton exchange membranes J. Mater. Chem. A, 2019 7:11847-11857.

- Liu L, Chen W, & Li Y A Statistical Study of Proton Conduction in Nafion?-based Composite Membranes: Prediction, Filler Selection and Fabrication Methods J. Membr. Sci., 2018 549:393-402.

- Liu L, Chen W, & Li Y An overview of the proton conductivity of nafion membranes through a statistical analysis J. Membr. Sci., 2016 504:1-9.

6 Limitation

Current models mainly focus on the types of polymers, fillers, fuels, reported. For novel materials, chemical structures, predictions are made based on knowledge, confidence needs validation in blind-test. We are not guarantee the prediction is fully accurate but guidelines are possible.

7 Bug reports and suggestions

Please contact either lyliu@ciac.ac.cn or yunqi@ciac.ac.cn for bugs or suggestions.

8 About us

We are a research group dedicating in structure and machine learning study on polymer materials. We are welcoming suggestions and collaborations. Please contact Prof. Yunqi Li for further information.